Magnesium Hydroxide

Price 150 INR/ Kilograms

Magnesium Hydroxide Specification

- HS Code

- 28161000

- Application

- Flame retardant, Wastewater treatment, Antacid, Neutralizing agent

- Physical Form

- Powder

- Grade

- Industrial Grade

- Product Type

- Inorganic Compound

- Shape

- Amorphous

- Taste

- Odorless, Tasteless

- Storage

- Keep in tightly closed container, Store in a dry, cool and well-ventilated area

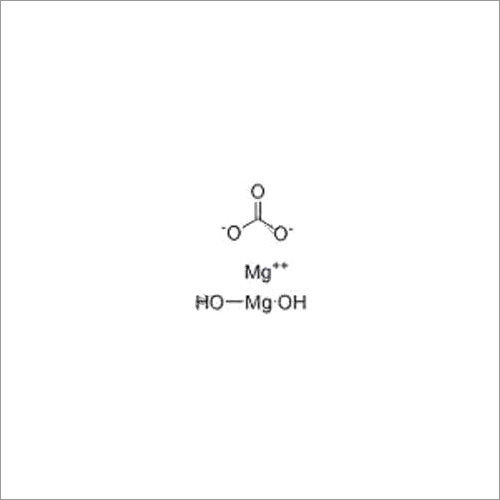

- Structural Formula

- HOMgOH

- Molecular Weight

- 58.32 g/mol

- Smell

- Odorless

- Refractive Rate

- 1.56

- EINECS No

- 215-137-3

- Solubility

- Sparingly soluble in water

- Properties

- White amorphous powder, Odorless, Slightly soluble in water, Antacid, Flame retardant

- Appearance

- White Fine Powder

- Poisonous

- Non-toxic

- Melting Point

- 350C (decomposes)

- Density

- 2.36 Gram per cubic centimeter(g/cm3)

- Shelf Life

- 24 months

- Molecular Formula

- Mg(OH)2

- Purity

- >98%

- Ph Level

- 10 (10% slurry)

- Usage

- Used in flue gas desulfurization, sewage treatment, and as flame retardant in rubber and plastics

- CAS No

- 1309-42-8

- Ingredients

- Magnesium Hydroxide

- pH (1% solution)

- ~10

- Packing Type

- HDPE bags with liner or as required

- Hazard Class

- Not classified as hazardous

- Loss on Ignition

- max 31.0%

- Stability

- Stable under normal temperatures and pressures

- Bulk Density

- 0.4 - 0.6 g/cm³

- Particle Size

- Typically <325 mesh

- Boiling Point

- Not applicable (decomposes before boiling)

Magnesium Hydroxide Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Supply Ability

- 100 Kilograms Per Day

- Delivery Time

- 1-3 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Magnesium Hydroxide

Magnesium Hydroxide

We bring forth for our clients an optimum range of Magnesium Hydroxide that was developed by us first in INDIA in the year 1977. Mainly used in antacid tablets and liquids and in laxative products, the Magnesium Hydroxide IP manufactured by us is practically insoluble in water and 95 per cent in ethanol. Apart from this, our pure Magnesium Hydroxide also finds application in flame retardants, rubber, plastics & ceramics, glass, effluent treatment, and other magnesium salts, food nutritional products along with vitamins and antioxidants, fuel oil, coal additives & stack SO2 absorption. This white, odorless powder is available to in different bulk densities in powder as well as paste forms as per the specifications of our clients in proper packaging. Owing to this capability, we have made our mark among the leading Magnesium Hydroxide Manufacturers and Exporters from India.

Grades:I.P./B.P./U.S.P.Specifications:

- Description :White or almost white, fine, amorphous powder.

- Solubility:Practically insoluble in water and in Alcohol. It dissolves in dilute acids

- Identification :The solution gives the reaction of magnesium.

- Appearance of Solution :Not more intensely colored than reference solution.

- Arsenic :Maximum 4 ppm

- Heavy Metals :Maximum 30 ppm

- Iron :Maximum 0.07%

- Chloride :Maximum 0.1%

- Sulphate :Maximum 0.5%

- Calcium :Maximum 1.5%

- Lead :Maximum 1.5 ppm

- Carbonate :Maximum slight effervescence

- Soluble Salt :Maximum 10mg

- Soluble Substances :Maximum 1.0%

- Substances insoluble in Acetic Acid :Maximum 0.1%

- Loss on Drying :Maximum 2.0%

- Loss on Ignition :30.0 to 32.5%

- ASSAY as Mg(OH)2:95.0 to 100.5%

- Microbial Cont. :E. Coli Enters bacteria and other certain Gram-ve bacteria are absent in 1gm

Specification :

- Arsenic : Not more than 4 ppm

- Heavy Metals : Not more than 30 ppm

- Chloride : Not more than 0.1%

- Sulphate : Not more than 0.5 %

- Calcium : Not more than 1.5%

- Iron : Not more than 0.08%

- Soluble Subs. : Not more than 1.0%

- Subs. insoluble in Acetic Acid :Limit 0.05% to 0.1%

- Assay(as Mg (OH)2) : Between 95.0% and 100.5%

- Loss on Ignition : 30.0 to 32.5%

Applications Across Industries

Magnesium Hydroxide serves diverse roles in various industries. It is a preferred choice for flue gas desulfurization in power plants, wastewater treatment facilities for neutralizing acidic effluents, and as an environmentally friendly flame retardant in plastics and rubber materials. Its non-toxic and non-hazardous nature makes it suitable for safe handling and widespread industrial usage.

Safe Handling and Storage

This product should be stored in tightly closed containers and placed in dry, cool, and well-ventilated areas to maintain optimal stability and performance. With a shelf life of 24 months, Magnesium Hydroxide remains effective when basic storage protocols are observed. The powders stability under normal temperatures and pressures further ensures ease of handling throughout its usage.

High Purity and Consistency

Produced to strict industrial-grade standards, Magnesium Hydroxide offers a purity greater than 98%. Its consistent particle size and amorphous structure help maintain the desired chemical reactivity and dispersion qualities, making it reliable for manufacturing, environmental, and remediation applications.

FAQs of Magnesium Hydroxide:

Q: How should Magnesium Hydroxide be stored to maintain its quality?

A: Magnesium Hydroxide powder should be kept in tightly sealed containers and stored in a cool, dry, and well-ventilated area. Avoid exposure to moisture and direct sunlight to ensure the product maintains optimal stability and a shelf life of up to 24 months.Q: What are the primary industrial applications of Magnesium Hydroxide?

A: Magnesium Hydroxide is widely used as a flame retardant in rubber and plastics, in flue gas desulfurization for power plants, and in wastewater treatment to neutralize acidic effluents. It is also utilized as an antacid and a general neutralizing agent in various chemical processes.Q: When is Magnesium Hydroxide used as a flame retardant?

A: Magnesium Hydroxide is employed as a flame retardant during the manufacturing of rubber and plastic products. When exposed to high temperatures, it releases water, helping to suppress fire by cooling surfaces and diluting combustible gases.Q: Where is this Magnesium Hydroxide manufactured and supplied from?

A: This industrial-grade Magnesium Hydroxide is manufactured and supplied in India, with packaging options tailored to meet transport and storage requirements efficiently.Q: What is the process for using Magnesium Hydroxide in wastewater treatment?

A: In wastewater treatment, Magnesium Hydroxide is added to acidic waste streams. It acts as a neutralizing agent, raising the pH and precipitating heavy metals, thus improving water quality before discharge or further processing.Q: What are the benefits of using Magnesium Hydroxide compared to other alkalizing agents?

A: Magnesium Hydroxide is non-toxic, non-hazardous, and provides a controlled, moderate alkalinity. This makes it safer and more environmentally friendly than stronger caustic agents, reducing corrosion risks and offering operational safety in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bulk Drugs Category

Magnesium Stearate

Price 50 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Usage : Industrial

Storage : Other, Store in a cool, dry place, tightly closed

Physical Form : Powder

Ingredients : Magnesium, Stearic Acid

Aluminium Hydroxide

Price 50 INR / Kilograms

Minimum Order Quantity : 25 Kilograms, ,

Usage : Industrial

Storage : Keep in a tightly sealed container, store in a cool, dry place, avoid moisture, Other

Physical Form : Powder

Ingredients : Aluminium Hydroxide

Almagate Chemical

Minimum Order Quantity : 25 Kilograms, ,

Usage : Industrial

Storage : Other, Store in tightly closed container, in a cool, dry place

Physical Form : Powder

Ingredients : Aluminium, Magnesium components

Heavy Magnesium Oxide

Price 50.0 INR / Kilograms

Minimum Order Quantity : 25 Kilograms, Kilograms

Usage : Industrial

Storage : Other, Store in a cool, dry place away from moisture.

Physical Form : Powder

Ingredients : Magnesium Oxide (MgO)

GST : 24AAAFE5387L1Z7

|

|

ELITE CHEMICAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry